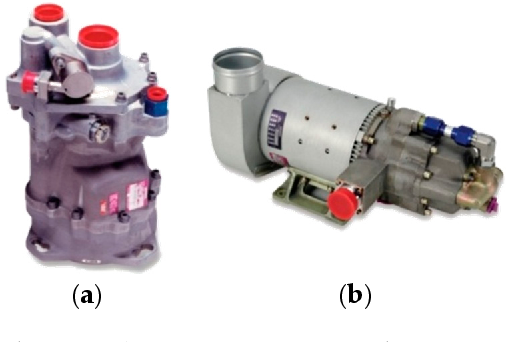

As soon as the voltage drops, a spring presses the nozzle needle back onto the valve seat and the bore hole is closed again. When the control unit applies voltage to the magnet winding, the nozzle needle rises up from its valve seat and releases a precision bore hole. Injection valves comprise a valve body, which houses a magnet winding and a guide for the nozzle needle, and a nozzle needle with magnet armature. The control unit calculates and controls the electrical pulses for opening and closing the injection valves on the basis of the current sensor data regarding the engine operating state. Injection valves are actuated electromagnetically.

To ensure the fuel is atomised effectively while minimising condensation losses, a certain engine-specific distance and injection angle need to be observed. The purpose of injection valves is to precisely inject the fuel quantity calculated by the control unit in all engine operating states.

0 kommentar(er)

0 kommentar(er)